At Chapman Maker, we understand the competition our business partners face. Our business partners have counted on our experienced engineering team for nearly five decades to give them a competitive advantage.

We focus on constant communication throughout the entire process, including the design phase, to ensure our business partner’s success. A dedicated Program Manager is assigned to each project. Through our partner’s ideas, our technical team can provide the design and development of the entire product structure and application program. This ensures our partners the highest level of quality, efficiency and cost effectiveness for each and every component manufactured.

Our team believes all stages in the development and production process of an application are important. We work closely with our business partners to ensure success throughout each stage. Our attentiveness to product development, design manufacturing and utilization of mold flows, to analyze and make design recommendations, provides our business partners with a competitive edge from the beginning.

In whatever stage you are during product development, our team is ready to assist and make recommendations for your designs to reduce both molding and secondary service costs.

We have worked with customers to develop products in some of the following fields:

1. Sports and Outdoors

2. Mobility / Accessibility

3. Health / Wellness

4. Industrial Tools

5. Industrial Machines

6. Construction

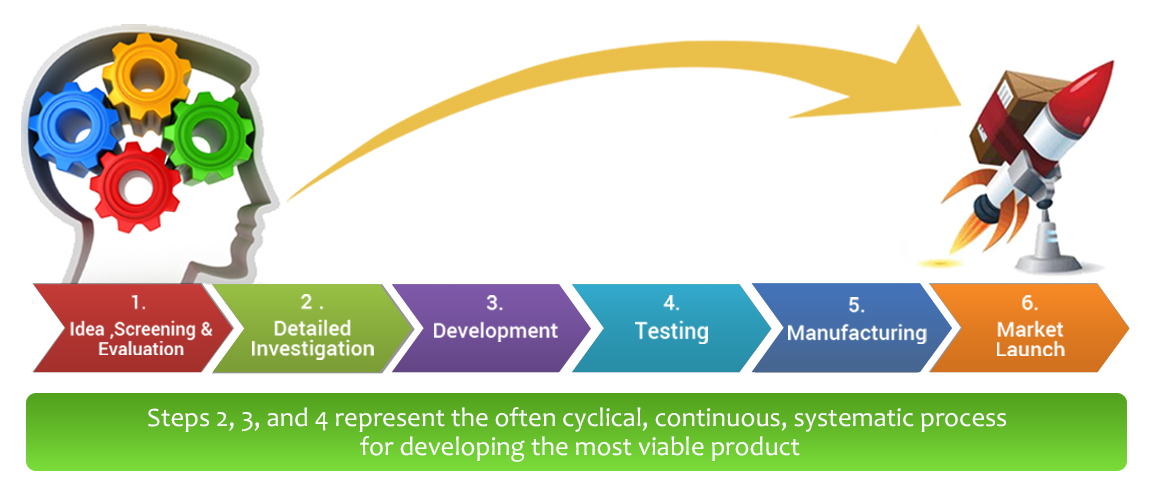

First step: The Idea - The project starts with your idea for a product. Let us help you define its essential functionality and visualize an approach that will work best for your target market. We will also benchmark and consider examining existing intellectual property.

Second step: A Detailed Investigation - While we determine the ID of a new product, our business marketing team needs to do market research to ensure that our product meets the current positioning and market demand. According to the results of our analysis of the market, we will optimize and upgrade the product’s structure and functions, and allow our products to enter the market quickly for sale.

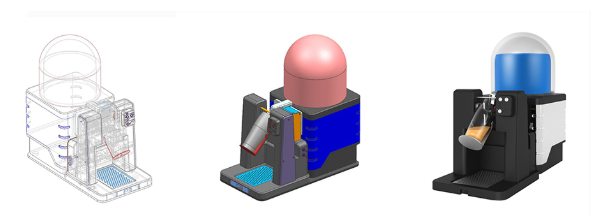

Third step:The Design - To make the best product for your business model, we’ll need to use the design-for-manufacturing (DFM) methodology so that production can be as efficient as possible. Concepts take shape in our 3D modeling programs, where we can make decisions about features, form factor, and materials. We will agree on the most sensible path forward for your product before advancing to the build phase.

Fourth step:The Prototype - In our fully-equipped facility, we can cut, mill, fabricate, 3D print, wire, and program each part and component before assembling your prototype. The prototyping phase may repeat as different designs are considered and tested.

Fifth step:The Manufacturing - As experts in manufacturing, automation, and industrial processes, we will help you design your product with scaling in mind to leverage savings opportunities down the road. Our in-house capabilities also allow us to fulfill production runs.

Sixth step: The Delivery - The first generation of your product is ready for production and the market. You'll have a complete design package, prototypes, and potentially a small run-in stock. You'll also have our support as you move through the next steps.

It is important to evaluate the business case and "business value" when developing a product. Our team will confidentially help you assess feasibility quickly and guide you through an analysis of the problem you aim to solve.